Variable atomization with hollow cone nozzles for spray dryers

So far the hollow cone nozzle has only been able to realize one throughput for a given pressure. Thus the mean drop size was fixed.

With the patented nozzles of swirl flow systems UG (limited liability) you can realize many different values for one pressure value, of course without changing nozzle parts during operation.

Vice versa many different values of pressure are possible for one value of throughput and so different values for the mean droplet size are obtainable. This will result in a different powder quality.

The nozzles can be used for many applications:

- milk powder, whey powder

- ceramic

- detergents

- food

- chemicals

- pharmaceuticals

- pesticides

- flavor, fragrances

- adhesives

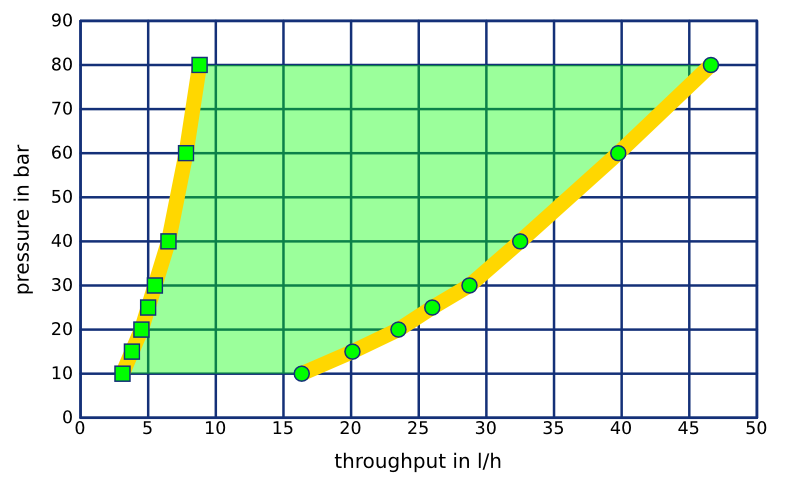

Typical throughput-pressure characteristic

The characteristic presented shows the operation area of variable nozzle. With a selected inner geometry of the nozzle (orifice plate and swirl chamber) the operation points can all be controlled within the highlighted area. Only one valve is necessary in order to set an operation point. This valve enables the setting of throughput, whereas the pump enables the setting of pressure.

The nozzle lances can be designed according to the user requirements, e.g. with the following options:

- different spray jet directions

- several nozzles fitted on a lance

- different materials

- different design limits for pressure and temperature

- control of several lances

The spare parts of various materials are delivered as well.

Your advantage:

- Use a well established principle of atomization and extend the capability of your spray tower.

- Adjust mean droplet diameter and throughput elegantly and smoothly during operation without changing nozzle parts.

- Use the nozzles longer in spite of wear without your product suffering quality losses.

- Reduce the number of spare parts for nozzles.

- Avoid wasting product due to lack of quality.

- Adjust the powder quality automatically, calibrating it as desired.

Upgrade the patented variable swirl-controlled atomization for your spray dryer!

Please get in touch!